Provision of Control room

Home / Projects

Project Details

Duration:

2022 – 2023

Client:

Pearl Petroleum ( Crescent – Dana Gas)

Start of the Project: Laying the Foundation for Excellence

This section details KNR’s scope of work for the Provision of the Control Room for Pearl Petroleum’s Crescent – Dana Gas project, completed between 2022 and 2023. Our focus was on delivering a fully functional and operational control room environment, including the installation of a dedicated Small Power and Lighting System.

The project’s success begins with a solid foundation.

- Collaborative Design & Planning: KNR engineers worked closely with Pearl Petroleum representatives to understand their specific operational needs and configure the control room layout. This included considerations for ergonomics, equipment placement, and operator workflow.

- Procurement of Building Materials & Equipment: KNR procured all essential building materials, furniture, and specialized control room equipment. This may have included raised flooring, soundproofing materials, operator consoles, display screens, and communication systems.

- Small Power & Lighting System Procurement: KNR sourced and procured a dedicated Small Power and Lighting System specifically designed for the electrical control building. This ensured reliable and efficient power supply for all control room equipment.

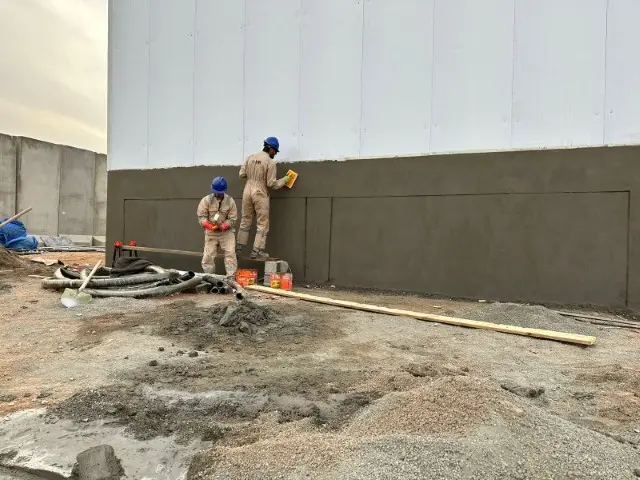

During the Project: Building With Quality and Safety at the Forefront

With the design finalized and materials procured, KNR’s team meticulously constructed and installed all control room components.

The project’s success begins with a solid foundation.

- Control Room Construction: KNR constructed the control room following the approved design, ensuring proper wall partitions, ceiling installation, and integration with existing building structures. Relevant safety features such as fire alarms and emergency exits were also included.

- Small Power & Lighting System Installation: KNR’s skilled electricians installed the dedicated Small Power and Lighting System within the control room. This involved meticulous wiring, electrical panel installation, and ensuring proper grounding and safety protocols.

- Equipment Installation & Testing: All control room equipment, including consoles, display screens, and communication systems, were installed and thoroughly tested to ensure functionality and seamless integration with the overall control room environment.

Finalizing the Project: A Smooth Handover and Ongoing Support

The final stage focused on ensuring a smooth handover of the fully operational control room to Pearl Petroleum and providing ongoing support, if needed.

The project’s success begins with a solid foundation.

- Project Handover & Documentation: Upon completion, KNR provided Pearl Petroleum with comprehensive handover documentation. This included detailed control room schematics, as-built drawings, operation & maintenance manuals for all installed equipment, and specific details regarding the Small Power and Lighting System.

- System Training & Performance Testing: KNR may have conducted training sessions for Pearl Petroleum personnel on operating and maintaining the control room equipment and the Small Power and Lighting System. Additionally, final performance tests were conducted to ensure the control room met all operational requirements.

- Ongoing Support & Collaboration: Beyond project completion, KNR remained available to offer Pearl Petroleum ongoing support. This may have included troubleshooting assistance, addressing any questions or concerns, and providing spare parts if necessary.